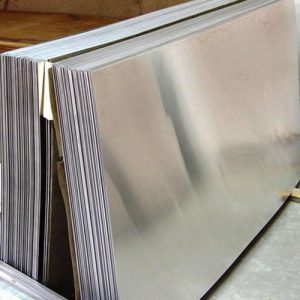

Metal sheets are thin and flat parts that have a wide range of applications. Aluminum sheets, which are also called aluminum plates, are the result of pressing raw aluminum and rolling it into plates. The aluminum sheet is made very thin and light, and at the same time it is strong enough to be easily installed and maintained, and it has great flexibility.

Aluminum sheet is made of light aluminum metal; due to its light weight and high strength in various industries such as: It is used in automobile manufacturing, airplane manufacturing, construction and household appliances. All kinds of aluminum sheets are produced during different stages; If all the processes are done correctly, they will increase the quality of these sheets.

What is aluminum sheet?

Aluminum ranks second after iron and steel in the world market. Aluminum is light weight, but the strength of some of its alloys is higher than construction steel. It has good electrical and thermal conductivity and is a good reflector for light and heat. Aluminum has high corrosion resistance in practical conditions and is a non-toxic metal.

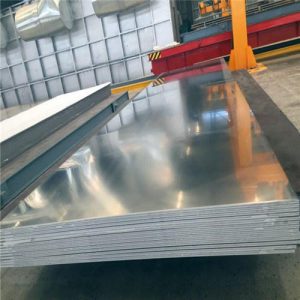

The method of producing aluminum sheets

The production steps of aluminum sheet are as follows:

- The raw material of aluminum sheet is aluminum ingot, usually they melt the aluminum ingot, and put the molten aluminum in continuous casting. The thickness of the casting roll is between 8-10mm, which is the first step in the production of aluminum sheet.

- Then the end rolling mill is subjected to repeated concentration of the casting roll to the desired thickness. This is the second step in the production of aluminum sheet.

- In the third step, it comes to refining and cleaning the casting roll, the refining is to refine the irregular edge of the roll, and the cleaning is due to the rolling mill in the case of the rolling material inside the rolling oil, the surface oil must be cleaned.

- At the end of annealing and packaging, the annealing is placed in a constant temperature annealing furnace for a while, through high temperature to change the internal grain size of the aluminum sheet to obtain a variety of mechanical and tensile properties, and then after finishing annealing. , through equipment for open processing, then packaging for all kinds of packaging.

All kinds of aluminum sheets

All kinds of aluminum sheets are available in different thicknesses. Aluminum is corrosion resistant and maintenance free. It has an excellent strength-to-weight ratio compared to other metals, weighing about one-third as much as iron, steel, copper, or brass. Aluminum plate has better thermal conductivity than any other metal.

Embossed aluminum sheet

This type of checkered plates are panels of sheet metal whose surface is made of embossed patterns and is raised to a height of 1.5 mm. It is thick and strong and resistant to impact and heat and is suitable for sidewalks, parking lots, loading bays.

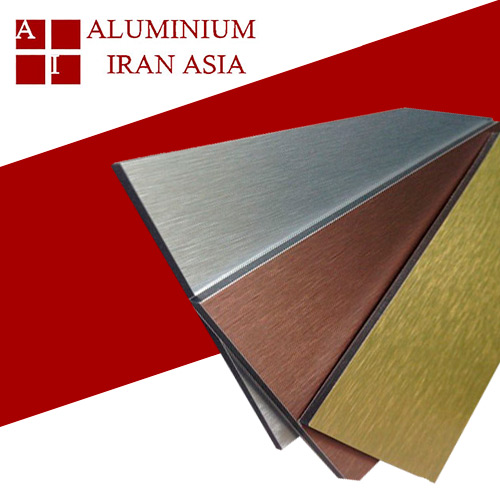

Brushed aluminum sheet

It is used for the facade of the building. Various types of it are available in the market such as anodized and composite panels. It has a shiny appearance.

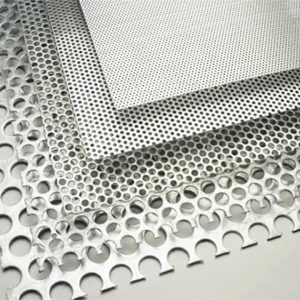

Perforated aluminum sheet

It is used in scenarios that are mainly chosen because of its beauty features. This is especially used in interior and exterior design works, for example, in the construction of various types of roofs, screens, solar shades and other architectures. It is used in places where its appearance is important.

Colored aluminum sheet

Colored sheets called “RAL”, which is a kind of color coding system, are implemented and provided by manufacturers in standard designs and colors. It is produced and marketed in various designs in the industry. Thin colored aluminum sheet is used in the decoration industry, cabinet making, roofs of houses or halls, etc. and is used in wavy or sheet forms.

6061 aluminum sheet

It is one of the most widely used and best types of aluminum sheet. In its construction, they use two elements, silicon and magnesium. The use of these two increases stability and resistance to heat and electromagnetic waves.

Aluminum sheet 2024

It has fracture toughness and high strength against cold, soldering and welding. Among its disadvantages is low resistance to corrosive agents and rust.

Aluminum alloy 5000

This type has high resistance to welding, corrosive agents and rust.

Aluminum sheet 1000

Among the types of aluminum sheets, the 1000 series is the most widely used type. Its properties include the following:

- Stability against heat and temperature

- Corrosion resistance

- High resistance to rust

- High formability

Composite aluminum sheet

They are used as light panels in exterior lighting or building facades. They are also called sandwich panels, which are lighter than solid metal and are easy to maintain and install. Composite panels are called ACS-ACP for short. It is made up of two very thin coated pieces that are coiled and bonded to the outside of a non-aluminum core.

7075 aluminum sheet

The high strength-to-weight ratio of these types of sheets makes them suitable for use in parts that are under stress, and it is one of the hardest aluminum alloys. It should be noted that this alloy reaches its hardest state after proper heat treatment. It has high resistance and strength.

Types of aluminum sheet thickness

All kinds of aluminum sheets are divided into thick and thin in terms of thickness. Its thick type from 25 micrometers is impermeable to oxygen and water. Its thin type is a little more permeable due to having small holes created by the production process.

Functional characteristics of aluminum sheet

Thanks to its properties, aluminum sheet can be used in various sectors such as restaurants, buildings, etc. Features of aluminum sheet:

Lightweight (about 1/3 the weight)

Formable or flexible

Being conductive (it has a higher electrical and thermal conductivity)

Corrosion resistant

recyclable

Application of aluminum sheet

- Making household appliances

- Pharmaceutical industry

- Transportation Industry

- Construction industries

- Food and drug packaging

- Insulation (as heat exchanger radiation shield and cable lining)

- Electromagnetic shield

- decoration

- military industries

- In some countries, it is used for minting coins.

The last word

In this article, we talked about the definition of aluminum sheet, its types and applications. As mentioned, these sheets are produced during cold rolling and hot rolling to resist corrosion and damaging factors. The types of aluminum sheet and its features have made it used in different industries.

Click to download the PDF