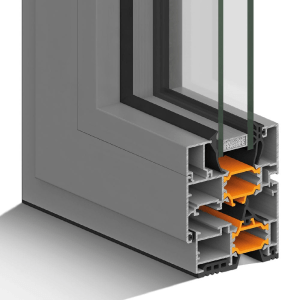

Thermal break profile is one of the new types of aluminum profiles that are used to make insulated aluminum double-paned doors and windows to increase the insulation factor. To make a thermal break window, a reinforced polyamide sheet is used as a barrier between the aluminum sheet. Thermal break profiles are made in such a way that thermal break doors and windows will be better insulated against cold, heat and sound.

Aluminum profiles have two types: simple (normal) and thermal break. Single-walled aluminum sheet is used in simple profile and double-walled aluminum sheet is used in thermal break profiles. It can be said that thermal break doors and windows use two aluminum profiles that are connected to each other with a polyamide blade. In fact, this polyamide material prevents heat transfer between the inner and outer sections of the window. It should be noted that the reason for using the term thermal break is due to the thermal break between two sections.

What is thermal break?

Aluminum metal is a metal with a high thermal coefficient and transmits cold and heat more than UPVC profiles. Therefore, even though there are ventilation points, due to the inherent properties of aluminum, heat can be transferred through the body of the profile. Although this exchanged heat is very small, but being optimal in today’s world is the first word. The problem can be solved by separating the inner part of the profile and the outer part of the profile with an insulating material. It can be said that thermal break profiles are a series of profiles that use polyamide or PVC strips to separate the inner part of the profile from the outer part. This insulation prevents heat transfer and is used to isolate structures that have high thermal conductivity.

Aluminum metal is not insulated against cold and heat, but when the insulating polyamide blade is placed between the profiles, the connection between the outer wall and the inner wall is cut off, and the aluminum profile is insulated and becomes a thermal break profile. Of course, the noteworthy point is that polyamide tapes are much better and more suitable than PVC tapes due to their durability and higher resistance. Thermal break profiles are more expensive than normal profiles, but based on the calculations, these profiles can return their cost after a maximum of 5 years. The high strength and hardness of aluminum has caused this metal to be used as a raw material in the construction of doors and windows.

The polyamide blades in the aluminum profiles of double-glazed windows make the heat transfer coefficient of aluminum decrease from 203 to less than 4. In fact, polyamide causes the interruption of conductivity in aluminum alloy. The best way to know if the blades used in thermal break windows are polyamide or not is to expose the blades to a direct flame. If the blade catches fire and smells like nylon, the blade is made of PVC, otherwise it is most likely a high-quality polyamide blade.

200 different color ranges are used in thermal break door and window systems. Electrostatic powder colors, anodize, and wood design are the three basic colors of thermal break systems. Aluminum thermal break anodized windows, in comparison with uPVC decorative and colored windows, show a better performance for hot, dry and tropical regions in terms of resistance and durability of color and quality.

Advantages of using thermal break double-glazed doors and windows

Thermal break double-glazed windows and doors transmit heat and noise about 100 times less than ordinary aluminum windows.

An additional layer is installed in thermal break double-glazed windows, which increases the security inside the building several times.

Thermal break windows have a long life and durability and are less subject to erosion and corrosion, so they do not require high maintenance costs.

The use of thermal break doors and windows causes a 38% reduction in thermal energy loss in winter, a 32% reduction in summer energy loss, a 28% reduction in fuel consumption, and a 20% reduction in initial investment costs of facilities.

The good material and construction method of thermal break windows have made these windows have many applications for earthquake-prone areas. Thermal break double-glazed windows have a flexible and good structure, and this flexibility is fully visible in the internal and external parts of the window.

The internal and external parts can have different colors, and according to the specific conditions of the project, different colored windows can be used.

If you are planning to buy the right window for a residential or commercial building, you may be hesitating between UPVC windows and specially designed thermal break aluminum windows. Compared to other types, thermal break windows are superior against various weather factors and reduce energy consumption.

However, other types of windows are still popular and used, and in different situations, both types of windows can be practical and affordable. Of course, in this situation, it is usually difficult and complicated for the customer to make a decision, and in these cases, we suggest you to contact elite experts, so that you can make the best and most economical choice by receiving expert advice.

These doors and windows are highly resistant to impact and chemicals, ultraviolet rays of the sun, and the lifespan of these profiles is very long.

Another important advantage of these systems is their moisture insulation, thermal insulation, and sound insulation. also

These systems are unworkable and highly compatible with their environment because they can be recycled.

Thermal break systems are extremely light and resistant to wind pressure, they are also resistant to pollution and dust.

These systems have high security against earthquakes and theft. They are very resistant to environmental factors such as sunlight, rain, time and discoloration.

Aluminum thermal break window has a lot of variety in the types of opening and it also creates the possibility of using a variety of fittings, and from the type of opening, we can mention the two-mode sliding Volkswagen. Therefore, thermal break aluminum double-glazed window system with a large variety in form, color and wide range of fittings and opening variety has been able to meet many needs of the building industry.

Therefore, the thermal break profile prevents the transfer of cold and heat. If this system is used in doors and windows, it will reduce the loss of thermal energy in the cold season by 38% and reduce the loss of cooling energy in the summer season by 32%, reduce fuel consumption by 28%, and reduce investment costs. We have completed the initial installation by 20%.

Nowadays, it has become very common to use aluminum frames because they are extremely light and highly malleable, because if we use a lot of the available glass, we have to somehow reduce the weight of the building, so aluminum is a good choice because of its lightness. is.

Electrostatic powder colors that are hardened in the furnace and anti-impact and spilled and are available to aluminum profile consumers with more than 250 different colors. It should be noted that, in addition, another coating and painting system, anadize, is applicable only for aluminum profiles.

Give the honor of building and executing the doors and windows of your building to Iran Asia Aluminum Group.

Pick up your phone now, and call the numbers below. Our consultants answer your questions.

We are your answer

Thermal break window specifications

The thermal break aluminum double-glazed window with thermal break is one of the types of thermal insulation windows. Due to the high heat transfer coefficient in aluminum, in addition to the fact that the glasses are double-walled, aluminum profiles are also considered double-walled because they are connected through polyamide blades, therefore, in this method of heat transfer in There is no profile. It is noteworthy that the energy loss in thermal break aluminum double-glazed windows is much lower than normal aluminum windows. Of course, it should be noted that in this type of window, if the material and type are not selected correctly, the thermal break window causes energy loss.

Due to the presence of polyamide rubber between the inner and outer walls of the profile, the thermal break window has reduced the possibility of heat, cold and vibration penetration to a minimum. Polyamide can also maintain its mechanical properties at high temperatures and against chemicals, water and UV rays, so they have high strength and longevity. The polyamide blade prevents the transfer of heat, that’s why the title of thermal break has been attributed to these windows.

Advantages of using thermal break windows

- Great style

- Thermal and sound insulation

- Being non-flammable

- Low maintenance requirements

- Safe against earthquakes and theft

- The use of sliding, hinged, lift and slide window systems and…

- Beauty, many color variations and desired

- Waterproofing

- Making windows in various sizes and designs

- Resistance to air pollution and dust

- High model variety including; Sliding, hinged, fixed, canopy and…

- Resistant to wind pressure while being light

- Recyclability and compatibility with the environment

- Resistance to color and shape changes caused by environmental factors such as sunlight, rain, etc.

Saving energy with thermal break doors and windows:

According to the statistics published by the Fuel Consumption Optimization Organization, the use of doors and windows with thermal break system on average reduces energy loss by about 34% in the cold and hot seasons of the year. Therefore, the fuel consumption and the initial costs of building facilities have been significantly reduced along with noise pollution in these types of windows.

Aluminum thermal break window price

Several factors are effective in the price of aluminum thermal break windows, which we will examine each of them below. The use of wooden and upvc windows to prevent cold penetration has been popular since long ago. But the durability, beauty and strength of the double-glazed aluminum window still attracts fans. Using a piece of polyamide or polyurethane to prevent heat transfer can be a time-consuming and costly process, so it is natural that the price of thermal break aluminum windows is higher than normal windows or upvc windows and wooden windows. However, aluminum windows have advantages that can offset the price of aluminum thermal break.

Conclusion

In the end, it can be said that Iran Asia Aluminum Group has the ability to design, produce and install all types of thermal break doors and windows with the benefit of a technical and expert team and the use of modern devices and close cooperation with prominent brands that produce aluminum door and window profiles. It has all over Iran and offers the highest quality thermal break aluminum door and window products.

Click to download the PDF